Tecap Automated Test Platform

Tecap ATP is a ready to use software package to control test systems and perform automated tests.

- Build up test stands fast and easy with software

- Interconnected Test Floors with central database

- Smart process capabilities for improved production test management.

- Electronics

- Semiconductors

- Mechanics

- Production

- Development

- Research

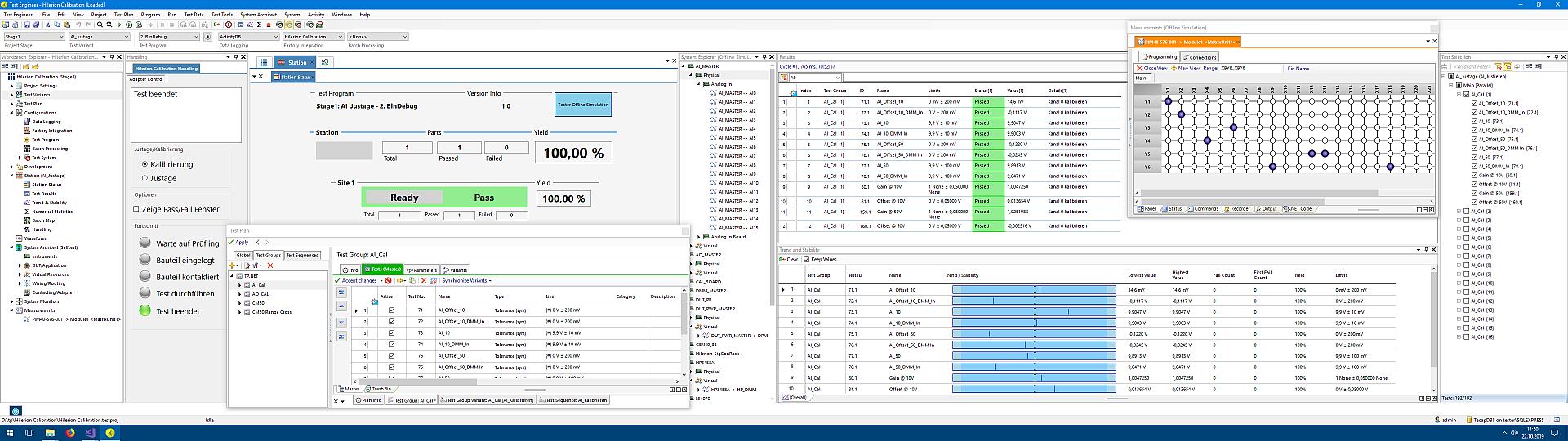

Modern, standardized test program development and diagnosis of functional test and in-circuit test are just as much a part of the repertoire as functions for the design and organization of tasks around the entire test process.

- The Tecap Platform brings with it everything for controlling test systems in the automated testing of electronic components and assemblies in production and development.

- Fully customizable to the customer environment: metrology, handling, data logging (DB, MES, etc.), setup procedures, operator interfaces, and workflows

- Test program development for functional test1) and in-circuit test2)

- Data logging and data management in SQL database, local and central (consolidatable)

- Test system configuration, test planning, program development with debugging, test execution, data analysis, package management for production release – all guided by user interface

1) by appropriate Platform Engine, which integrates the programming technology in the Tecap Platform. The scope of delivery includes the .NET-TP Engine for the operation of functional tests based on .NET test programs, additionally requires a Visual Studio / Sharp Develop IDE

2) The Tecap CompactTSVP ICT Platform Add-On Pack can be used to make a combination test out of FCT and ICT on the Tecap PlatformProgramming and using measurement units and test systems

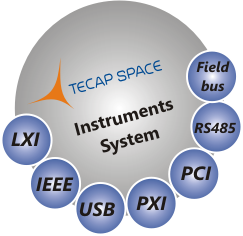

The Tecap Platform is hardware-open. Any type of measurement technology and test systems can be integrated.

For the use of common instruments, there is our manufacturer pack (Tecap Instruments Pack) as an add-on for installation.

This means that many hundreds of standard devices can be programmed and applied immediately via a graphical user interface.

Direct driver programming is omitted.

- Control of Automated Test Equipment (ATE) for functional test and in-circuit test

- Operation of test facilities with adapters and PLCs

- semi- and fully automatic testing of electronic components and assemblies

- Final Test in Production

- Test of pre-series and sample series

- Standardized test program development

- Adaptable to your own system environment (customizing) – 100% usable after installation with standard elements

Developing test programs

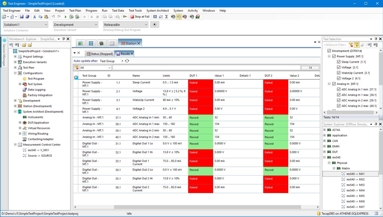

The Tecap Platform includes features for capturing and evaluating test results. These functions directly show the results and numerical statistics live during the test run on the screen. To assess the quality level of the DUT, test program and test system, live data on process and machine capability serve as a basis for evaluation. This result and statistics data can be stored directly in a report file (Excel, PDF, etc.), in the Tecap Database or in an MES system.

- Creation and management of entire test projects

- Development of test programs

- Sequence and variant management

- User-interface based system configuration and system operation

- Debugging and diagnostics

- Live data for test results and numerical statistics

Managing and organizing the test process

The structure of the test programs is the same across the different test projects and test systems. So you have a very high recognition value. Based on Tecap's extensive engineering and customizing capabilities, any desired test process can be mapped. This can achieve a fundamental standardization.

- Gathering the test specification

- Connecting to data management systems (ERP/MES)

- Safe release of test projects for production test

- Integration and configuration of adaption and handling systems

- Communication with manual or automatic manufacturing systems

- User interfaces for setup and operator personnel in production

Platform Apps

- Test Engineer

Project configuration and program development, debugging, analysis, etc. - Test Operator

Test operation in production - Result Analyst

Insights into result and analysis - Test Planner

Editing test plans withouth engineering license

- Distribution Server

Server application for the distributed Tecap Database over arbitrary transport routes (Share, MessageBus, FTP, etc.) - Database Replicator

Station application for performing database synchronisation by schedule or events - Database Manager

Managment and organisation of databases for Microsoft SQL Server and MySQL - Installation Assistant

Tool for licensing, configuring pin locks, creating plugin setups, etc.

Instruments Pack

The instrument library with popular manufacturers contains several hundred ready-to-use devices and is constantly being expanded.

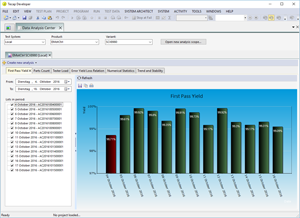

Features for data recording and analysis

To draw conclusions from the test data, which are more than pass/fail, there are numerous evaluation functions in the Result Analyst.

Features for semiconductor test

The Tecap Platform offers plug-in interfaces for connecting wafer probes.

Configuration of wafer maps and binning are just as much a part of the repertoire as sampling tests and STDF data logging.

Automotive * Consumer * Semiconductors * EMS * Medical * Aerospace * Power * Sensors * Industrial

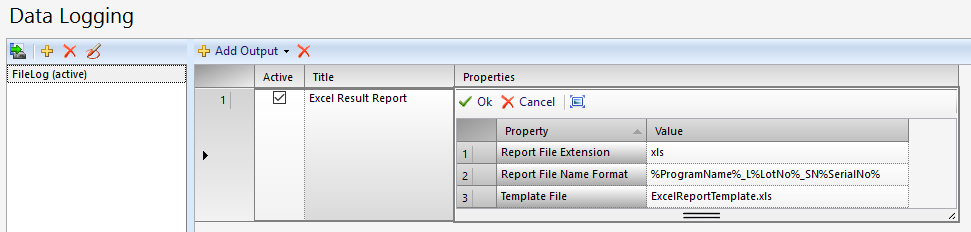

Datalogging

Configurable data logger can be attached per Variant. Independently from if you want to store into a databse or into the file system, Tecap does this job for you.

By this means, different profiles for development and evalutation can be used, than for mass production.

The test program itself contains no datalogging related source code.

- Open data logging interface

- Data logger are attached by configuration

- Several data logging profiles per project and by that differently useable per sequence variant

Software Downloads

Tecap

Automated Test Platform

Version 22.6.0

Licensing

Features in Tecap 2022

- Decentralized, distributed database organization with background replication; enables decoupled, self-sufficient test stations

- Added support for MySQL databases

- Database Manager Application for organizing and managing databases and distribution

- Contacting with monitoring of the degree of wear

- Reusable factory integration configuration with settings per variant

- Learn batch structure (wafer, tray, etc)

- Import / export batch structure (wafer, tray, etc).

- Direct debugging of released production projects at the station

- Pin lock for dev applications in production

- Numerous usability and stability improvements

Tecap Features

- Multiple Platform Engines – combination of multiple software- and programming environments and techniques to realize a test program

- Flexible modular system to configure a project for sequences and variants, setups for test systems, setups for data logging, the DUT, usw.

- Independent development stages within one project to build and extend the test program for different development phases of the DUT (e.g. prototyp, sample, final)

- Creation and execution of workflows with chained test setups to realize multi-stage production processes

- Live display of test results and statistics during test run in the user interface in compact presentation

- Numerical statistics for machine capabality analysis MSA1+3 (cpk/cgm, etc.)

- Ready-to-use data reporting for test results and statistics, e.g. database, Excel format, PDF, etc.

- Modern graphical user interface and user experience

- System Architect – all definitions and configurations of the testsystem including adaption and DUT/UUT by operating the user interface

- Parallel test scalable by configuration (Multi-Site Test)

- Full entry of the system wiring

- Automatic signal path finding (Auto-Routing) from measurement instrumentation to the DUT/UUT

- Ready-to-us High Level Integration of measurement and stimuli devices and switching modules in the Tecap Instruments Pack

- Production Package Management

- Plugin architecture for easy customizing – adaption to your specific system and software environment

- Customizing of data logging, test handling, visualization of setup procedure and operator mode

- Functions for dynamic test plan creation from external sources, e.g. ERP/MES

- Service mode for production enviroment

- Integrated role-based user authorization system

- Unit system with automatic result conversion

- Configuration of power line frequency (50Hz/60Hz)

- Waveform Manager – Central organization of waveforms with saving to database

- Quality alarms for better production monitoring (Stop after n Fails, Yield Drop, etc.)

- Conditional Tests

- Quality relevance of tests (Pass/Fail, Monitoring)

- Wafer/Tray Mapping

- Wafer/Tray Sampling

- New Datenbase Design for distributed usage on stations and servers

- Logging of service actions to datenbase per station

- Result Analyst for data analysis – cpk/cgm, distribution, trend/stability, wafer/tray maps

- Improved Test Plan Editor

- Test Plan Infos synchronized to .NET Code comments

- Serial Number Tracking

System Requirements

Operation System

- Windows 10, Windows 8/8.1, Windows 7

- Microsoft® .NET Framework 4.5.2

Test program and plugin development

- Microsoft Visual Studio 2019/2017/2015/2013

- Visual Studio Community 2019/2017

- SharpDevelop 5

Database

- Microsoft SQL Server 2016/2014/2012 und Express Edition

- MySQL